In the fast-paced world of construction, efficiency and accuracy are essential for staying ahead of the competition. Quantity takeoff (QTO) is one of the most critical processes that can significantly impact the success of your projects. It provides precise calculations of the materials needed, allowing for proper budgeting, procurement, and planning.

For contractors, subcontractors, and quantity surveyors, mastering quantity takeoff is the key to delivering projects on time and within budget.

What is Quantity Takeoff?

Quantity takeoff, often abbreviated as QTO, is the process of estimating the quantities of materials required to complete a construction project. This estimate is based on the project’s plans, drawings, and specifications. It’s an integral part of construction cost estimation, ensuring that all materials are accounted for in the procurement phase.

Quantity takeoff covers a wide range of materials, including concrete, steel, timber, electrical wiring, piping, and more. Whether you’re working on a small residential build or a large commercial project, quantity takeoff allows you to streamline material procurement, minimize waste, and ensure cost accuracy.

Why Quantity Takeoff is Essential for Construction Success

Proper quantity takeoff ensures that you’re not only ordering the correct amounts of materials but also avoiding the expensive errors that can arise from over- or underestimating. Here are some key reasons why quantity takeoff is essential for the success of any construction project:

Cost Control: A well-executed takeoff helps control costs by providing an accurate material estimate upfront. This prevents unnecessary expenses due to material overages or shortages.

Time Efficiency: Accurate takeoff reduces delays caused by running out of materials or waiting for additional deliveries. You can maintain a smooth workflow, keeping your project on schedule.

Waste Reduction: By calculating the exact material needs, quantity takeoff reduces waste, promoting sustainability and lowering disposal costs.

Improved Budgeting: Quantity takeoff is critical in creating a realistic budget. Knowing the exact amount of materials required helps contractors avoid underestimating, leading to better cash flow management.

The Quantity Takeoff Process Explained

The quantity takeoff process involves several steps, each of which is crucial to ensuring the accuracy of the final estimate. Here’s a breakdown of the key phases:

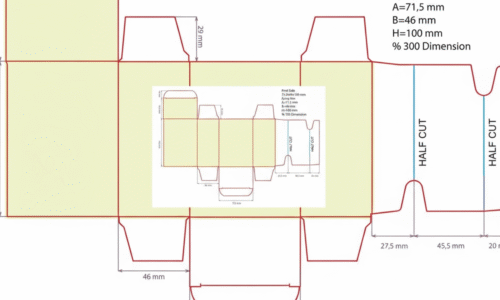

Analyzing Project Documents: Start by reviewing all project documents, including architectural drawings, blueprints, and specifications. This gives you a complete picture of what materials are needed.

Identifying Quantifiable Materials: Determine which materials need to be quantified. This includes everything from foundation materials like concrete to finishing items such as paint or tiling.

Using Takeoff Software: Many professionals now use digital tools like Bluebeam Revu and PlanSwift for takeoffs. These programs allow you to measure directly from digital plans and calculate quantities with precision. Not only does this speed up the process, but it also reduces the likelihood of human error.

Calculating Quantities: Measure each material needed and calculate the quantities based on unit rates. This might involve converting lengths, areas, and volumes into their corresponding material amounts.

Cross-Checking for Accuracy: Before finalizing the takeoff, cross-check your calculations with the project specs to ensure everything has been accounted for. Errors in this stage can lead to costly delays down the line.

Common Challenges in Quantity Takeoff

While quantity takeoff is a crucial part of project planning, it comes with its challenges. Here are some common issues professionals face and how to overcome them:

Inaccurate Drawings: Sometimes, the project drawings or specifications provided may not be 100% accurate or up-to-date, leading to potential miscalculations. Ensure you’re working with the most recent versions of the drawings and verify details with the design team if necessary.

Human Error: Manual takeoffs can be prone to errors, particularly on complex projects with many material types. Leveraging digital takeoff tools helps minimize these risks and allows for easier adjustments.

Changing Project Scope: The scope of a project can change during construction, affecting the quantities needed. It’s important to stay flexible and revisit the takeoff periodically to account for any changes in the scope.

Tools and Technologies for Accurate Takeoffs

Modern technology has revolutionized the quantity takeoff process, offering digital solutions that improve accuracy and save time. Here are some of the top tools used in the industry:

Bluebeam Revu: Bluebeam Revu is one of the most widely used takeoff software tools in construction. It allows users to mark up PDFs of project plans, measure materials directly from the drawings, and collaborate with team members in real-time.

PlanSwift: PlanSwift is another popular tool that offers easy integration with project plans and specifications. Its drag-and-drop interface makes it simple to measure quantities and generate accurate takeoffs.

Kubla Cubed: Especially popular for civil projects, Kubla Cubed is used for earthwork and excavation takeoffs. It allows users to calculate soil volumes, cut and fill quantities, and other vital data with ease.

Excel Spreadsheets: While digital tools have taken center stage, many professionals still use Excel for finalizing takeoff estimates and creating detailed material lists. Combining Excel with digital takeoff software allows for greater customization and flexibility in reporting.

How Measure Manage Can Help

At Measure Manage, we specialize in providing accurate and efficient quantity takeoff services for residential, commercial, and civil projects across Australia. Our team of expert quantity surveyors ensures that your material estimates are precise, helping you avoid costly overruns and delays.

Here’s how we stand out:

Expertise Across All Project Types: Whether you’re working on a small home renovation or a large infrastructure project, our team has the experience to handle it all. We provide detailed takeoffs for everything from basic building materials to complex structural components.

Digital Tools for Accuracy: We leverage the latest technology, including Bluebeam Revu and Kubla Cubed, to ensure accuracy in every takeoff. This allows us to deliver faster, more reliable estimates for your project.

Commitment to Quality: As members of the Royal Institute of Chartered Surveyors (RICS) and the Australian Institute of Quantity Surveyors (AIQS), we are committed to maintaining the highest standards in everything we do. Your project is in safe hands with Measure Manage.

Why You Need Professional Takeoff Services

Mastering quantity takeoff is no small feat, and many contractors find it more efficient to outsource this task to professionals. Hiring a dedicated quantity takeoff service like Measure Manage ensures that your estimates are precise and that your project stays on budget from start to finish.

If you want to eliminate the guesswork and focus on delivering quality construction, leave the takeoff to the experts.

With Measure Manage’s digital solutions and industry expertise, you can rest assured that your materials are accounted for accurately and efficiently.